Pneumatic Conveyor : Flexible Feeder

Flexible Feeder

The flexible feeder is a compact suction pneumatic conveyor suitable for short-range transportation by a suction-type air carrier to transport powdered and granular raw materials automatically

Feature of Flexible Feeder:

- Simple Structure: The structure is simple, internal cleaning can be easily performed. It is the most suitable method to convey various types of raw material.

- Operational Flexibility: The suction can be chosen as nozzle type or hopper type. Tank size can be simply changed by a retainer.

- High-Efficiency Dust Filtration: Scatter of dust is prevented by the internal filter. The filter washing mechanism is adopted by the pulse-jet method.

- Stability/Compactness: Utilizing a special filter cross leads to apparatus compactness.

- Cost Efficiency: The cost is reduced due to mass production.

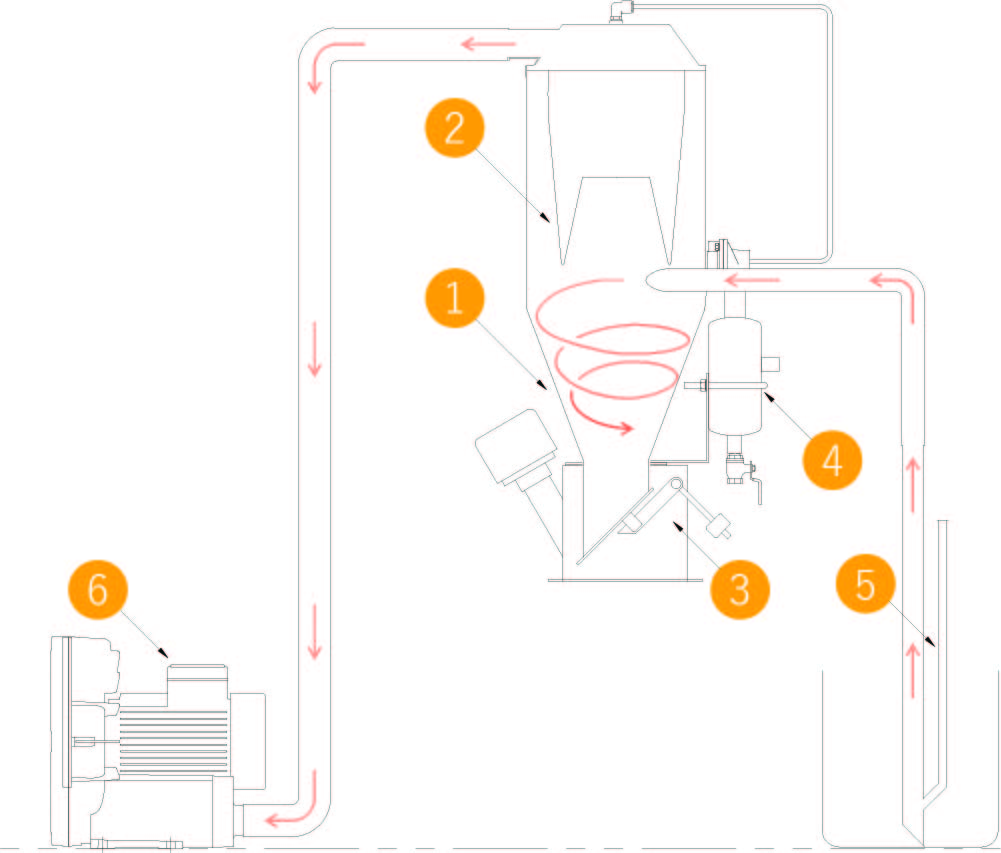

Internal Structure and Principle:

Internal Structure and Principle:

- Put the suction nozzle into raw material's hopper (It can be connected directly at the bottom of raw material's hopper).

- Start this machine by a panel.

- Suction is started by operating blower, and the raw material's are moved into the Flexible Feeder.

- Because suctioned raw materials and the air are separated by filter, the exhaust from a blower is stored in the Hopper.

- After the blower is automatically stopped by timer control, raw material in hopper are discharged by a free-fall damper.

- When raw material discharges, the filter is washed by pulse-jet method using compressed air from the air tank.

- The process becomes continuous loop after repeating steps 3-6 mentioned above.

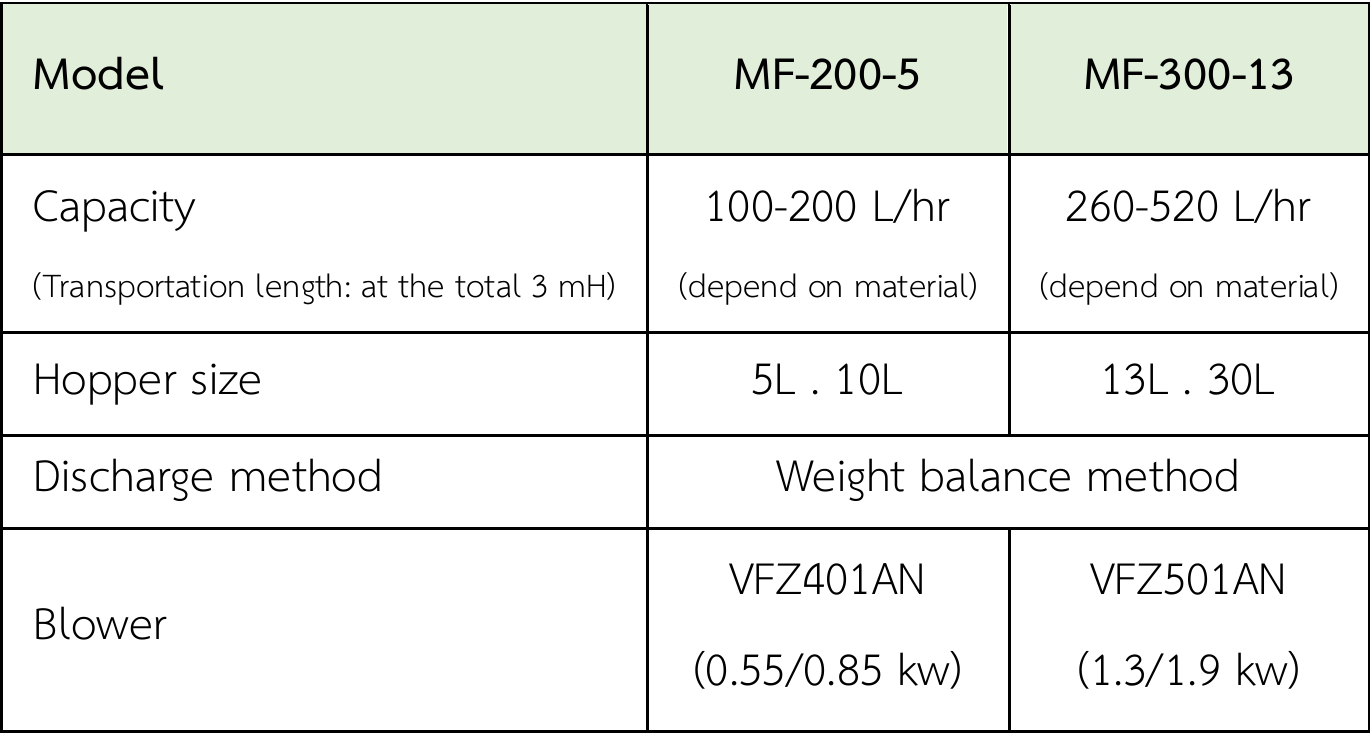

Specification

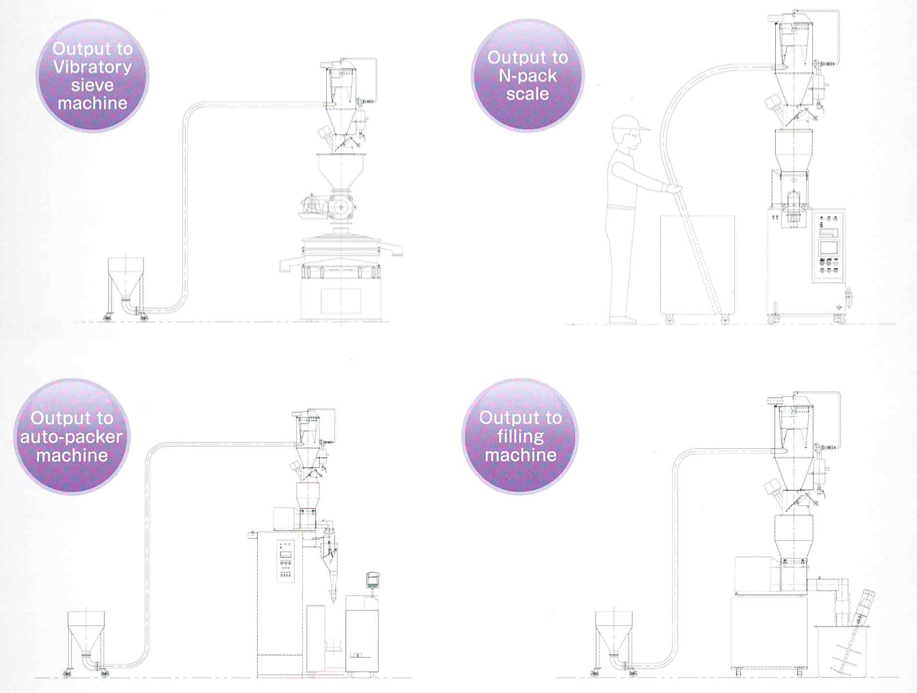

Application Example